SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SHINI PLASTICS TECHNOLOGIES INDIA P.LTD.

Auto Loaders

Introduction"Stannards" Self-contained SAL-330 / 360 series adopt single phase carbon brush motor with superior suction power and easy installation. It is particularly suitable for conveying new materials. SAL-430 / 460 series use a three phase inductive motor with low noise level and long service life. It also has an automatic motor reverse cleaning device.

Vacuum Hopper Loaders

We hold expertise in manufacturing highly efficient range of Separate Vacuum Hopper Loaders or SAL-G series “Standard”. Precision engineered, these loaders are suitable for conveying material over long distance. The range is offered in two models including SAL-700G/800G/800G2, which are for one to one combination, while SAL-900G/900G2 that are ideal for one to two combination. Further, to ensure no contamination to raw material all the models adopt stainless steel hopper. Designed in compliance with set industry standards, these high efficiency high pressure blower features light weighted, durable, great suction power, easy installation and operation.

Separate Vacuum Hopper Loaders Ug

We have in our stores precision engineered Separate Vacuum Hopper Loaders-UG that are based on the established design specifications. The designing pattern adopted has added features like more attractive appearance, better performance, and improved ease of operation. Manufactured using high grade raw material and advanced machines, the whole range comprises of seven models equipped with vacuum blower from 1 to 15 HP. Further, to meet the requirements of the clients, the economical models can also be manufactured.

Hopper Loaders

SAL-U series self-contained hopper loaders are suitable for conveying virgin material and adopt European design with stainless steel hopper to avoid material contamination. In addition, it has an attractive appearance a sound-proof motor cover to reduce noise level and a top handle to enable convenient movement. Also the remote operation has been realized by using a detachable control panel.

Separate Vacuum Hopper Loaders (Sal Ug)

51243.jpg)

SAL-UG series separate-vacuum hopper loaders are based on the established design and now feature more attractive appearance, better performance, and improved ease of operation. The whole range comprises of seven models equipped with vacuum blower from 1 to 15 HP. Economy models can be offered on request.

Multi Station Loaders

Separate hopper loaders are designed and developed on the basis of original European separate-vacuum hopper Loaders. They feature more functions, easy to operate, and convenient to install. This model, equipped with a high pressure blower and two SHR-U-S type European central vacuum hoppers, is applicable to two dehumidifying and drying machines (dehumidifying dryer "SDD") or one gravimetric blender "SGB" to process plastic materials. Besides that , it can also realize the "One-to-Two" way of conveying materials to different moulding machines or hoppers to greatly lower the cost.

Multi Station Loader

Multi Station Loader / "One-To-Four" Separate Hopper Loaders (SAL-UG124)

"One-to-Four" Separate hopper loaders are designed and developed on the basis of original European separate-vacuum hopper Loaders. They feature more functions, easy to operate, and convenient to install. This model, equipped with a high pressure blower and four SHR-U-S type European central vacuum hoppers, is applicable to four dehumidifying and drying machines (dehumidifying dryer "SDD") or one gravimetric blender "SGB" to process plastic materials. Besides that , it can also realize the "One-to-Four" way of conveying materials to different moulding machines or hoppers to greatly lower the cost.

Vacuum Powder Loaders (Sal Ugp)

51247.jpg)

SAL-UGP series separate-vacuum hopper loaders has all features that come with SAL-UG series product. There is also double-stage blower available as an option. Different model of hopper is available for each individual output capacity needs, especially suitable for 30% and 100% powder loading.

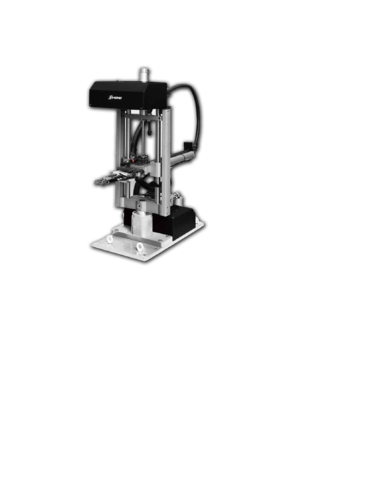

Flexible Screw Loader

The spiral conveyers, newly launched by SHINI, employs the rotary motion of may occur.

SSC series flexible screw feeders adopt motor-driven screws for raw material conveying, applicable to convey regrinds, virgin materials, powders and their mixtures with features of low noise level, easy installation and maintenance. Two models of SSC-50/65 available with max. horizontal conveying capacity of up to 1,900kg/hr. Besides using in plastic industry, they can also apply in food, chemistry, pharmacy and other various applications.

Inclined Belt Conveyors Cb

Shini manufactures five model of belt conveyor as follows under technical license from a leading european manufacturer:

CB series conveyors feature reliable performance and ease of operation and are suitable for conveying sprues or finished products to a higher level beside the moulding machine.

Belt Conveyors With Separator (Cbd)

51251.jpg)

Shini manufactures five model of belt conveyor as follows under technical license from a leading european manufacturer:

CBD series conveyors feature reliable performance and ease of operation and are suitable for conveying finished products to separator to separate product from its connecting sprues. The height is adjustable.

Belt Conveyor With Metal Detector (Pnl Ms)

51253.jpg)

PNL-MS belt conveyor with metal detector is a device which can detect the metal contained in the material during conveying and simultaneously activate the alarm. It is suitable for not only working together with Shini’s granulator, such as SG-36, SG-43, SG-50 and SGS series, but also working with other series of belt conveyors. PNL-MS series feature reliable performance, easy operation and convenient height adjustment upon customer’s requirements.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

51164.jpg)

51166.jpg)

51252.jpg)

51256.jpg)